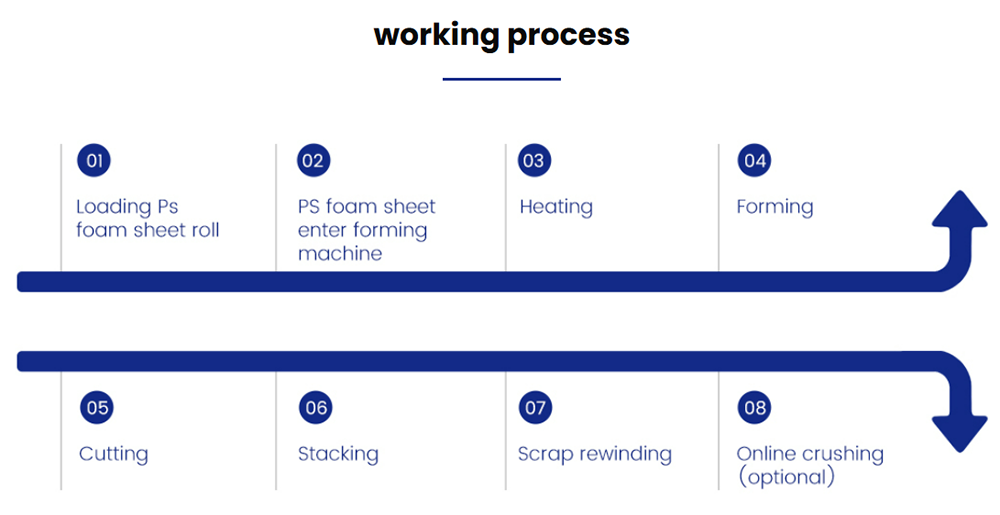

PS Food Container Forming Machine,in our factory,is part of the PS Foam Food Container production line. It is a hot seller and has received a lot of praise. This machine is an all-powerful thermal forming machine with integration of vacuum forming, press forming and synthetical forming.

Main parts

1.Forming System

The forming method adopts the comprehensive forming of vacuum, air pressure and mold pressing which are close at present. The vacuum pump is a high-quality vacuum pump; the upper and lower molds of the hydraulic station are separate.

2.Cutting off system

Hydraulic automatic control, the maximum pressure reaches 60 tons, and the workbench is controlled by a photoelectric switch.

3.Stacking System

We provide fully automatic manipulators, which can automatically stack and controlled by PLC.

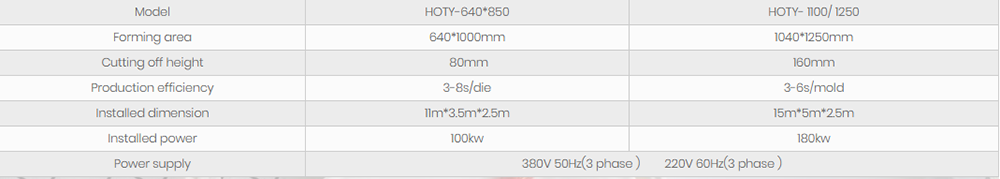

Specifications

We have two models:HOTY-640*850、HOTY-1100/1250. Through compulsory recycling, renewable granulation, the production of low-grade hard plastic products, packaging products, daily necessities and other renewable resources. This machine an produce different sizes of take-out boxes.

Advantage

Our core selling point is fully automatic manipulators, which can automatically stack and controlled by PLC, and the stacking quantity can be set arbitrarily,which saves manpower and greatly improves efficiency. Can be selected according to customer needs.

1. High precision molding: It can produce PS foam fast box with accurate size and regular shape.

2. Efficient production: with fast molding speed, improve production efficiency.

3. High degree of automation: it can realize automatic operation, reduce manual intervention, and improve production stability.

4. Strong adaptability of molds: can adapt to different specifications and shapes of molds to meet diversified product needs.

5. Cost reduction: Through efficient production and effective use of materials, reduce production costs.

6. Improve product quality: The surface of the molding fast box is smooth, uniform texture, and has good physical properties.

7. Energy saving and environmental protection: compared with traditional production methods, it may consume less energy and have less impact on the environment.

8. Easy to operate: easy to operate and maintain, reducing the requirements for the skill level of the operator.

Application

Applicable industries are hotels, restaurants, home, food stores, food and beverage stores.For some hotels and restaurants, it is possible to save costs by not buying , but producing for your own use.

Warranty

Choose our quality is not to worry! Our factory has been in operation for a long time and we have a lot of experience.

We will record the video of the machine before it is released from the warehouse, The core parts are guaranteed within one year, and after sale, we will provide engineers overseas to guide the use of the machine.

About us

Longkou Hongtai Machinery was founded in 1991 with a registered capital of 5 million. Over the past 30 years, relying on its own technical strength, the company has successively developed plastic foaming machine series, fast food box forming machine, fruit cleaning, waxing and sorting machine series, pearl cotton (EPE polyethylene) foaming cloth machine, and recycled cotton forming unit Equipment and other series total more than 20 varieties of products. Existing Shanghai, Suzhou, Changzhou, and other cooperative production units.

If you are interested, please contact us as soon as possible!

Facebook:LongKou HOTY Industrial Machinery

Phone/whatsapp/wechat:008613406503677

Email: melody@lkhoty.cn

Display of finished products

Post time: Jul-03-2024