PS Foam Recycling Machine, this machine is also known as-Waste Plastic Polystyrene Foam Recycling Machine. PS Foam Recycling Machine is an important environmental protection equipment. It is specially designed for recycling polystyrene foam materials. Through advanced technology and processes, waste PS foam is transformed into reusable resources. The machine has the advantages of simple operation and high efficiency, which can effectively reduce the pollution of foam waste to the environment and make positive contribution to the recycling of resources, and has high economic and environmental protection value.

Main parts

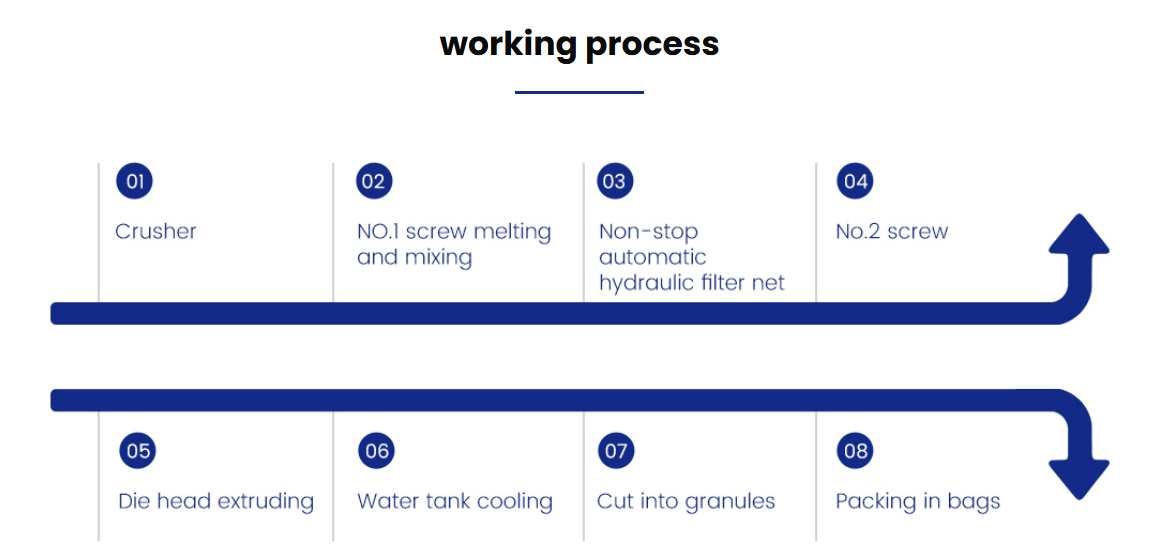

The whole machine consists of crusher, main machine, cooling tank and granulator. Its equipped with quick motor-operated filter-screen-replacing unit and automatic temperature control.It adopts single screw, double stage plasticification, increasing compress ratio.

lt is the ideal equipment to recycle the waste materials It features compact structure and easy operation.

This line is of new design, reasonable configuration, steady operation, low noise, low consumption and high output.

1.Crush Part:blades made of special material, with high hardness easy operation to change blades or screen mesh high capacity with stability

2.Recycle Part

The waste plastic is heated and melted by the hot air, and the melted plastic melt is extruded and granulated through the screw, so the noise and dust are avoided, and the working conditions of the workers are improved; through Controlling the temperature of the hot air can prevent the plastic from degrading due to excessive temperature during the melting process, and the hot air can be recycled, which reduces energy consumption.

3.Electric Cabinet

It adopts Frequency exchanger, Electronic component and Temperature controller. Independent electrical cabinet control system, easy to operate and control, install equipment, troubleshoot, etc.

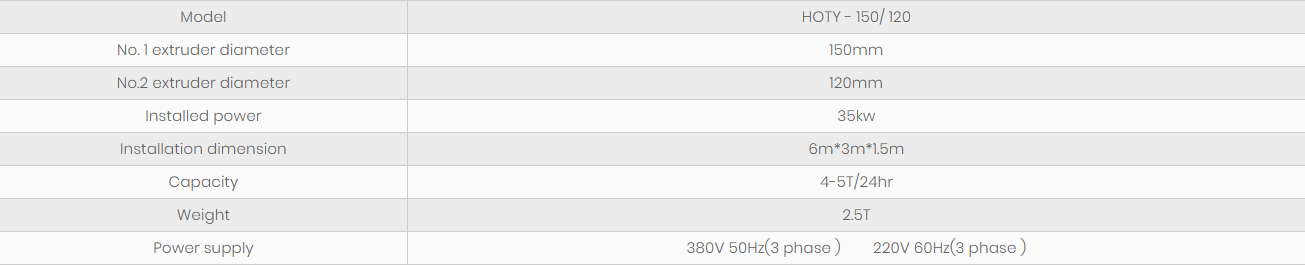

Specification

Advantage

1. Multifunctional processing: It can handle various shapes and sizes of PS foam, including block, flake, crushed particles, etc.

2. Efficient crushing: equipped with a powerful crushing device, the foam can be quickly crushed into smaller particles.

3. Compression capacity: Effectively compress the foam volume, greatly reducing storage space and transportation costs.

4. Automatic operation: with automatic feeding, crushing, compression and discharge functions, reduce manual intervention.

5 Resource recovery: To achieve the recycling of PS foam, reduce resource waste and environmental pollution.

6 Low energy consumption: energy-saving technology is used to reduce operating costs.

7. Small occupation space: compact structure, relatively small footprint, suitable for installation and use in different sites.

Warranty

Choose our quality is not to worry! Our factory has been in operation for a long time and we have a lot of experience.

We can ensure:

1.The buyer should place the machine to the right position and inform the supplier after the

machine reach the buyer’s factory.

2.The seller will send engineers to instruct installation, commissioning and training. They will

stay there until it running in normal state. (The buyer bears expenses on accommodation, hotel, and two ways flight tickets and pays each engineer 150USD/day as subsidy.)

3.Within 1 year:If the machine have any problems, we will provide spare parts for free

More than 1 year: Buyer should pay for the spare parts .

If you are interested, please contact us as soon as possible!

Facebook: LongKou HOTY Industrial Machinery

Phone/whatsapp/wechat: 0086-13406503677

0086-18554057779

Email: melody@lkhoty.cn

Display of finished products

Post time: Jul-05-2024