The Asia-Pacific region is expected to account for the largest share

China is an emerging economy in the Asia-Pacific region with an exponential growth in the number of manufacturing activities. The reason for this is because many end-user industries require high-performance plastic parts.

●Among the types of plastic processing machinery, injection molding machinery is expected to occupy a significant share in China. These are well-known enterprises in this market segment, such as Haitian International Holdings Co., LTD., Zhenxiong Group, Lijin Technology Holdings Co., LTD., Datong Machinery Enterprise Co., LTD., Fuqiang Xin Machinery Manufacturing Co., LTD

●In addition, the production data of bottled drinking water indicates that the injection molding machinery market in China is expected to grow during the forecast period. Just like in China, injection molding machines are likely to have a large share of the plastic processing machinery market in the country.

●Some of the well-known players in this market segment include Abor LTD, Engel Machinery India Pte LTD, Haitian Huayuan Machinery (India) Pte LTD and Husky Injection Molding Systems Pte LTD, among others. According to the Indian Brand Equity Foundation (IBEF), the plastics industry has more than 2,000 exporters and contains more than 30,000 processing units and about 85-90% of these units are smes.

●The Japanese government plans to reduce its carbon footprint through the use of electric vehicles, which has led to significant investment in the development of electric vehicle infrastructure. The number of electric vehicle charging stations in Japan has increased to keep up with the growth in the number of electric vehicles. That's because the government started offering subsidies to people who buy electric cars.

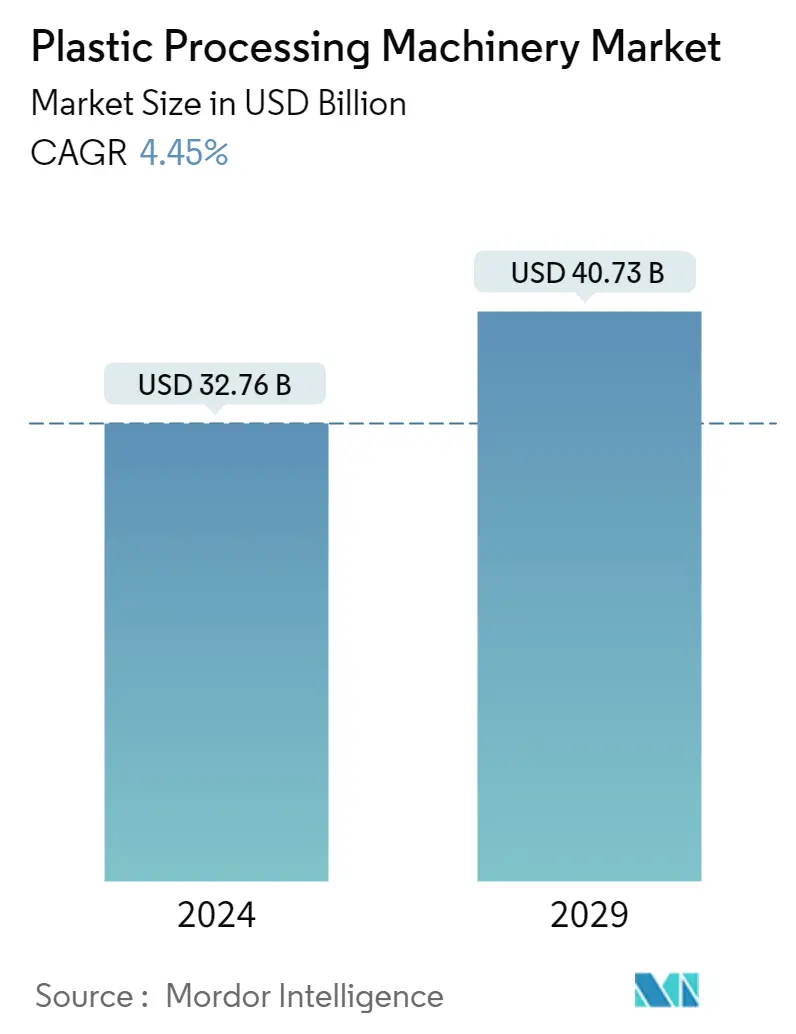

Plastic Processing Machinery Market Scale forecasting

The plastic processing machinery market size is expected to be $32.76 billion in 2024 and is expected to reach $40.73 billion by 2029, with a compound annual growth rate of 4.45% during the forecast period (2024-2029).

Plastic molding processing technology has been widely used in the manufacture of various products, such as auto parts, connectors, displays, mobile phones, 3C electronic products, plastic optical lenses, biomedical applications, general daily necessities and so on. Plastic molding processing technology is getting better and better day by day. Because more and more people use the product in different ways and have different needs for how the product works.

Compared with other materials such as metal, stone and wood, plastics have the advantages of low cost and strong plasticity. Therefore, it has been widely used in economy and daily life. Plastic products and industry occupy an extremely important position in the world. The growth of the market is expected to be driven by trends including the expanding demand for reinforced and biodegradable plastics. The industry is embracing the concept of Industry 4.0 by integrating digital technologies with plastics manufacturing technologies.

Due to the substantial growth in the demand for plastic products, the industry's demand for plastic processing equipment has also grown significantly. Plastic injection molding is one of the most common plastic molding methods than other methods. With numerous industrial applications, the market demand for this technology continues to expand and develop. For many industries that need to manufacture large numbers of high-quality parts at low cost, custom plastic injection molded parts are the perfect solution.

The increasing demand for upgrades in developing countries and the modernization of plastic processing plants are expected to stimulate the demand for replacement of injection molding machinery and other equipment. Technological changes have also contributed to this growth, lowering equipment costs and making them cheaper in price-sensitive markets.

The global plastics processing machinery market is expected to grow rapidly. There is growing awareness of the many benefits of plastic processing technology, such as design flexibility, and the food and beverage and other end-use industries are rapidly beginning to adopt such machinery.

Post time: Jun-25-2024