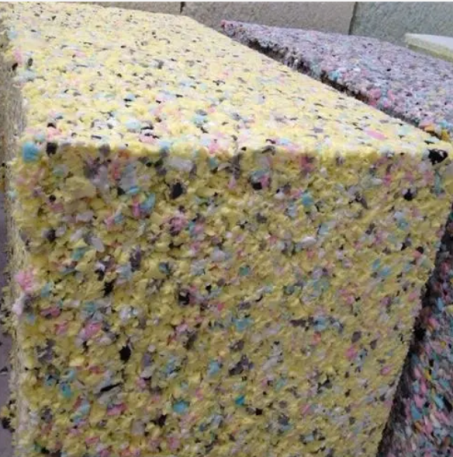

1. Rebonded sponge:

Recycled sponge is a kind of recycled product that belongs to the scraps of polyurethane products. It is made of industrial sponge scraps that are crushed, stirred, sterilized, sterilized and deodorized by high-temperature glue steam and compressed into shape. The production cost is greatly reduced in terms of production cost and use. Because a large amount of glue needs to be added during the production process, the sponge smells very pungent. Therefore, recycled sponge can cause harm to human health and is not recommended.

The main deep-processing products of recycled sponges are as follows: 1. Various types of low, medium and high-end furniture sponges, laminate sponges, shoe sponges, bust sponges, etc. 2. Production of polyester and polyether foams of various densities and deep processing of products (such as Polyester cartridge sponge, cosmetic sponge) 3. Various color sponges, fireproof sponges, anti-static sponges, filter sponges, wood pulp sponges, pearl sponges, wave sponges 4. Various types of sponge pillows (such as slow rebound sponge pillows, healthy magnetic sponges Pillows and various sponge mattresses) 5. Sponge accessories (such as clocks, canning, printing, luggage, and other packaging sponges) and shaped processing products 6. Various sponge products (such as toys, household items) 7. Insulation material products 8. PVC, PE, PP, PS, AES and other rubber and plastic products

2. Memory foam:

This type of sponge, also called slow-rebound cotton, will slowly return to its original shape after being deformed by external force. That is, the material has a characteristic of both viscosity and elasticity, absorbs impact kinetic energy, and can be used repeatedly without permanent deformation.

3. EPE Foam :

EPE pearl cotton is a non-cross-linked obturator structure, also known as polyethylene foamed cotton. It is a new type of environmentally friendly packaging material. It is composed of low-density polyethylene grease that is physically foamed to produce countless independent bubbles. It is specially processed using a high-pressure process. It is the smallest molecule and has the highest resilience among all sponges. After compression, the pearl cotton is tightly arranged in a bead shape. As it is used, the internal stress of the pearl particles will gradually be released. , has the characteristic of becoming more fluffy with use, so waist bags processed with pearl cotton have particularly good fullness and are very resilient.

Adding special material epe pearl cotton, it has anti-static properties. It is also an environmentally friendly material that can be recycled. It is widely used in fields such as construction, mechanical and electrical engineering, furniture, household appliances, instrumentation, craft gifts, wood products, glass ceramics, precision parts packaging and insulation.

epe pearl cotton has the advantages of water and moisture proof, shockproof, sound insulation, heat preservation, good plasticity, strong toughness, recycling, environmental protection, and strong impact resistance. At the same time, epe pearl cotton has the advantages of heat preservation, moisture proof, anti-friction, anti-aging, and corrosion resistance. and a series of superior usage characteristics. It also overcomes the shortcomings of ordinary foam rubber such as brittleness, deformation, and poor recovery. It can absorb and disperse external impact force through bending. Has very good chemical resistance. It is an ideal substitute for traditional packaging materials. However, the cost of pearl cotton is relatively expensive, so it is generally only used among small pillows and lumbar pillows that are used most frequently and destructively by customers.

4.PU sponge

PU foam is produced using traditional methods. PU foam is made by reacting an isocyanate polymer with a polyol.

The raw materials of polyurethane foam include isocyanate, polyol, biologically derived materials, chain extenders, chain linkers, catalysts, surfactants, etc. By mixing these two liquid streams, PU foam is created. There are many things that go into the polyol stream, and the two streams are called polyurethane systems. PU foam is known by different names in North America and Europe. Depending on the chemicals added, various densities and hardnesses are introduced into PU foam. Two different types of catalysts are used in polyurethanes. The main function of the catalyst is to enhance nucleophilicity. Autocatalytic processes are also carried out in the production of PU foam. PU foam is not durable compared to other foams.

The main use of PU foam is in highly elastic soft foam seats. Rigid foam insulation panels, microcellular foam seals and gaskets. Pu sponge packaging is mainly used in packaging, sofa, furniture, clothing and other industries. Packaging sponge is an environmentally friendly material suitable for product inner packaging to play a protective role in buffering and shock absorption. Anti-static sponge not only protects electronic products and chips like ordinary sponges, but also has an anti-static effect, protecting electronic products from static electricity damage. Pu sponge lining: delicate feel, strong resilience, not easy to deform after long-term use, and smooth cutting. Sponge lining plays the role of insulation, shockproof, dustproof, filling, sound insulation and fixation for products in various industries. Packaging sponge lining is suitable for all mobile phones, computers, cosmetic gifts, speakers, toys, lighting, car radios, gift boxes and other ancillary products. Product size, color, shape and quality can be customized according to customer needs.

Post time: Jan-12-2024