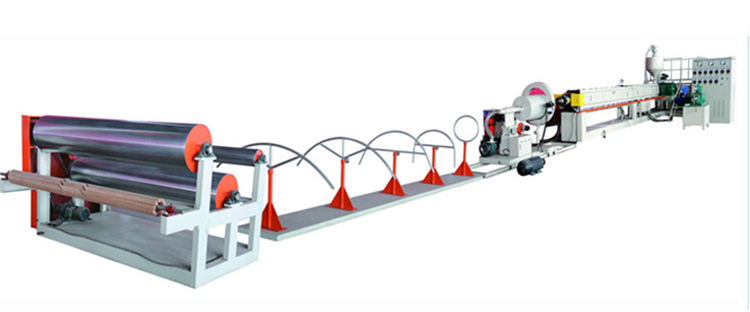

epe polystyrene foam sheet extrusion production line

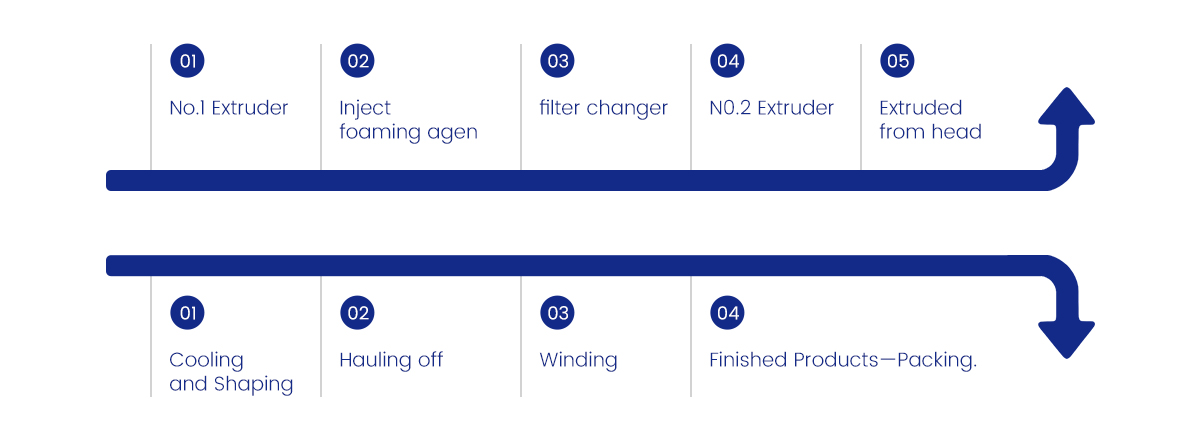

working process

machine description

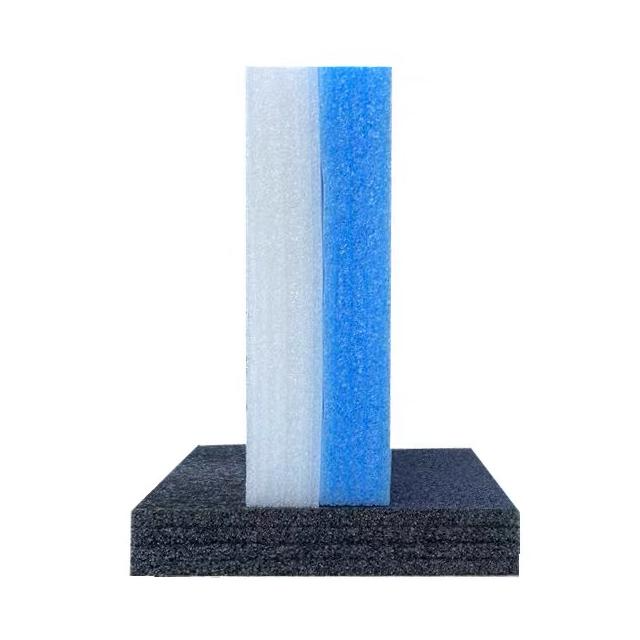

The foam sheet has the features of dampproof, shockproof, soundproof, heat preservation, and good plasticity. After laminating, the foam sheet will get high dampproof performance. These products are mainly used for placing underfloor.

Extruder

Screw bolt and barrel material: 38CrMoAlA 38CrMoAlA nitrogen treatment.

Main motor style: Three-phase asynchronous motor with frequency converter.

Speed reducer: Extruder dedicated reducer, hard tooth surface, high torque, and low noise.

Heater: Cast aluminum heater, solid-state relay contactless output, intelligent temperature controller control temperature.

Cooling type: Circulating water cooling, automatic by-pass system.

Head and mold

Strcture: Round of the extruder head, mold mouth can adjust.

Material: High quality carbon forged steel, heat-treated, flow channel surface roughness: Ra0.025μm.

Diameter of mold orifice: Depend on the width of production.

Electric cabinet

It adopts Frequency exchanger,Electronic component and Temperature controller.Independent electrical cabinet control system, easy to operate and control, install equipment, troubleshoot, etc.

Product display

Polyethylene foam Sheet, also named as pearl cotton. It’s a kind of new –type packing material with the features of damp proof, shock proof, sound insulation, heat preservation and good plasticity. It is an ideal substitute of traditional packing materials, and widely used in the packing of fruit, instruments, bags & luggage, shoemaking, household appliances, electronic product, hardware, furniture, fragile goods, etc.